The Best Guide To Inventory Management

Wiki Article

The Buzz on Inventory Management

Table of ContentsGetting The Inventory Management To WorkNot known Facts About Inventory ManagementHow Inventory Management can Save You Time, Stress, and Money.Inventory Management Fundamentals ExplainedThe Greatest Guide To Inventory Management

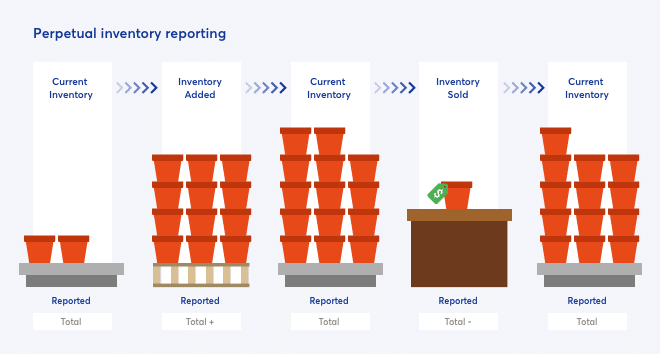

The routine supply system is an approach of stock assessment for economic reporting objectives in which a physical count of the supply is executed at details periods. This accounting approach takes supply at the start of a period, includes brand-new stock acquisitions throughout the duration and also subtracts ending supply to obtain the price of goods marketed (GEARS).They can associate several data points to the number, consisting of the supplier, product measurements, weight, and also variable information, such as just how many remain in stock. RFID or radio frequency identification is a system that wirelessly sends the identity of a product in the kind of a special identification number to track products as well as give detailed item information.

Inventory Management Things To Know Before You Get This

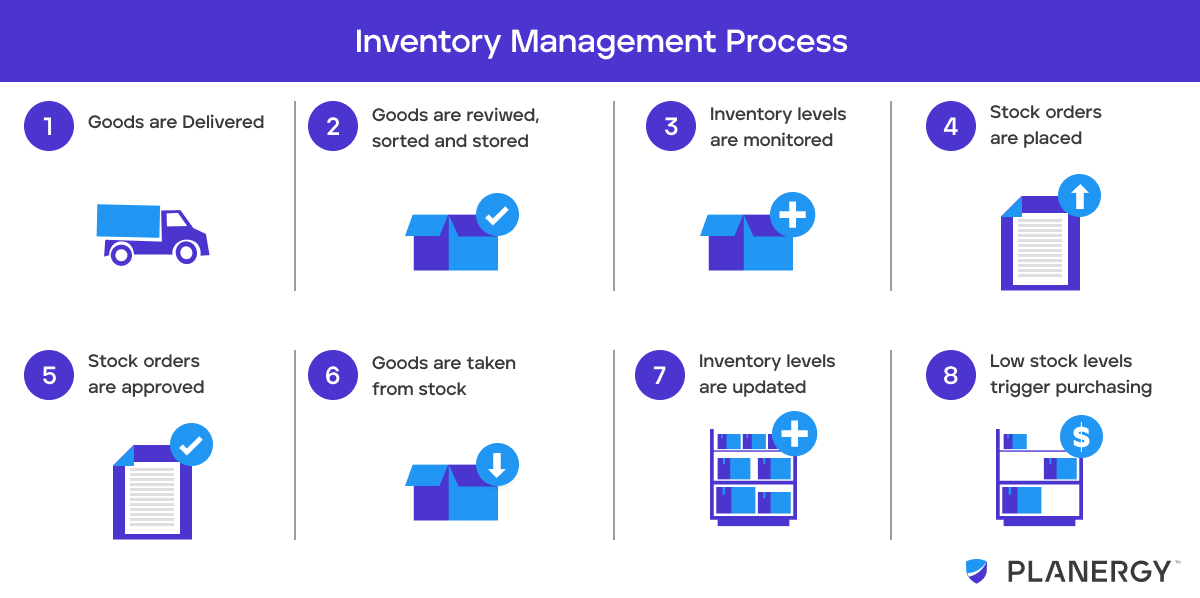

Stock management refers to the procedure of storing, buying, and also selling of goods and services. One of the most essential aspects of inventory monitoring is taking care of the flow of raw materials from their procurement to end up products.As an example, an oil depot can keep a significant inventory for a long period of time. Or for businesses that sell disposable goods, such as fast-fashion items, continuing top of your supply can be really pricey. One means to account for stock is by grouping it into 4 classifications: first-in-first-out, last-in-first-out, weighted-average, as well as first-in-first-out.

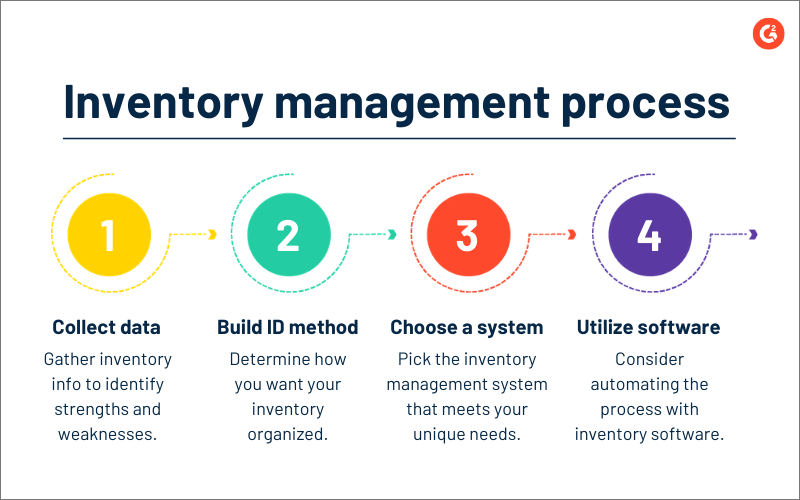

Relying on the sort of business that it is taking care of, different inventory monitoring methods are made use of. Some of these consist of JIT, product requirement planning, and days sales of supply. Various other techniques of examining inventory can additionally be utilized depending on nationwide and regional laws. The SEC requires public business to report the existence of a so-called LIFO get.

The Inventory Management PDFs

Learn much more regarding stock management from Walton College's Supply Chain Management program's introduction on the subject covering everything from projecting to aim versions: Among the most valuable properties of a company is its stock. Inventory Management. In different sectors, such as retail, food services, as well as production, a lack of supply can have destructive results.Having a huge inventory can additionally lead to a reduction in sales. Both for little businesses and large companies, having a proper supply monitoring system is extremely crucial for any type of business.

Stabilizing the dangers of overstocks and lacks is a specifically difficult procedure for companies with complex supply chains. A business's stock is commonly a present possession that it plans to offer within a year.

More About Inventory Management

Not only will it serve to boost performance, but it's likewise beneficial for preventing theft with the assistance of product monitoring as well as safety. Supervisors can also aim to use their supply administration strategy to monitor sales treatments which leads to much better solution.

Providing consumers a number of various kinds of internationally-grown produce continue reading this in both organic and non-organic varieties at an economical cost, also when the fruits and also vegetables aren't in season, is a modern-day marvel many thanks in component to stock monitoring. Looking after stock in actual time and even establishing automated replenishment systems is mission-critical to many.

The Ultimate Guide To Inventory Management

6 million bundles from their brand name to third-party sellers daily. Their Smart Stockroom makes use of robot and also human aid to do the job, but it's inventory management that keeps everything rolling. According to Technology Vision, "Amazon.com's management strategy, along with all that automation, have actually made business amazingly lean and suggest by historical standards." The inventory management of bathroom tissue companies remained in the hot seat in very early 2020 as panic-buying brought about lacks across the country.

Below are the major types you should know: Raw materials, This describes pieces of your item that requirement to be shipped to you as well as constructed by your group. Inventory systems that track these need to account for distributor timelines. Underway, Products made hop over to here from resources as well as are currently being constructed or organized fall under this category.

Report this wiki page